● Fasteners: screw, bolt, nut, washer, rivets, nails etc.

● Fasteners: screw, bolt, nut, washer, rivets, nails etc.

● Plastic/Rubber Parts: wall anchor, rubber o-rings, toys, lego building bricks, small plastic parts.

● Hardware Parts: hardware components, hardware connectors, metal parts etc.

● Furniture Accessories: furniture connectors, furniture fasteners, furniture fittings, furniture accessories, door handle, hinge etc.

● Others: small hardware or plastic parts, regular shape or irregular shape of parts.

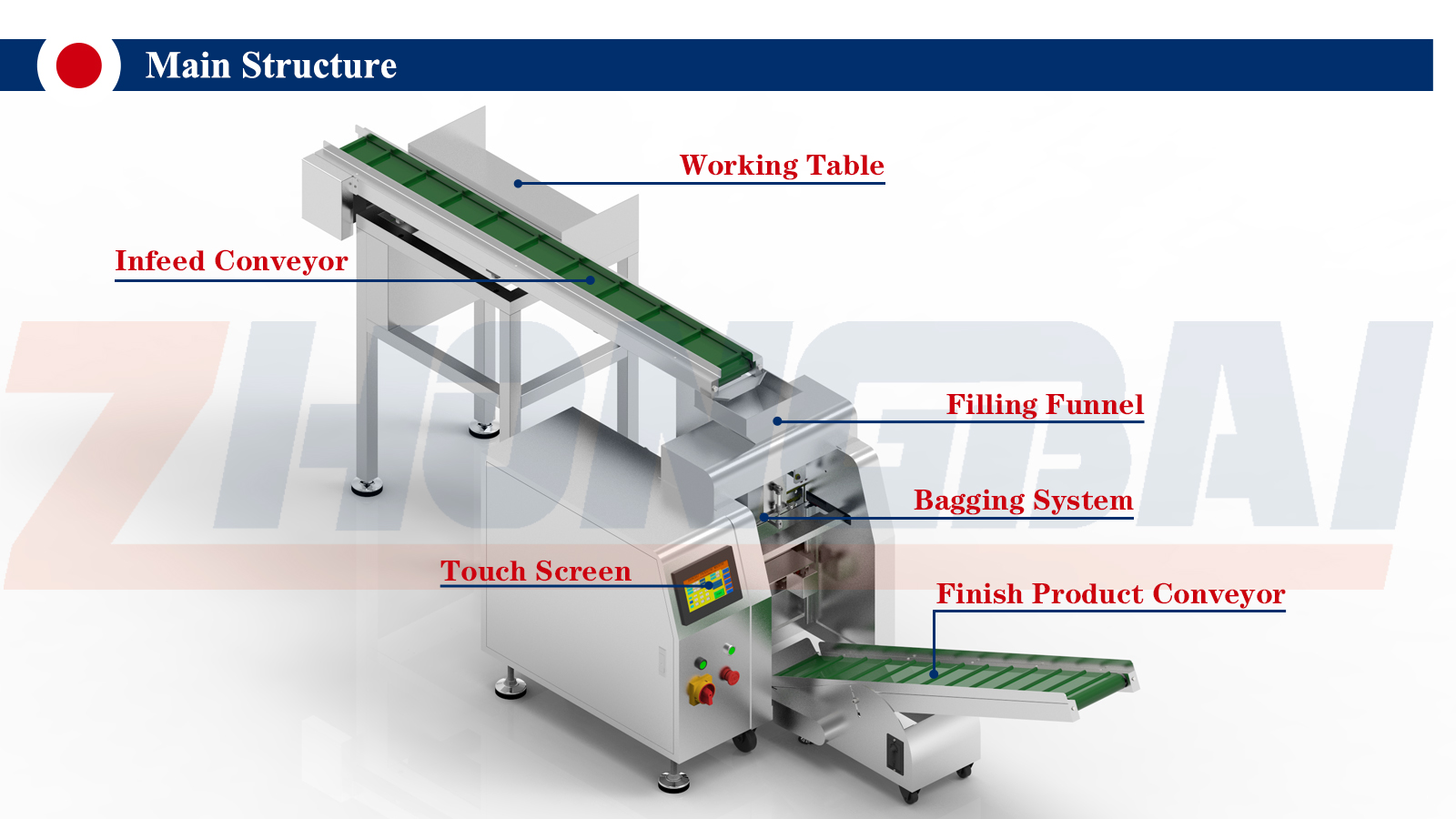

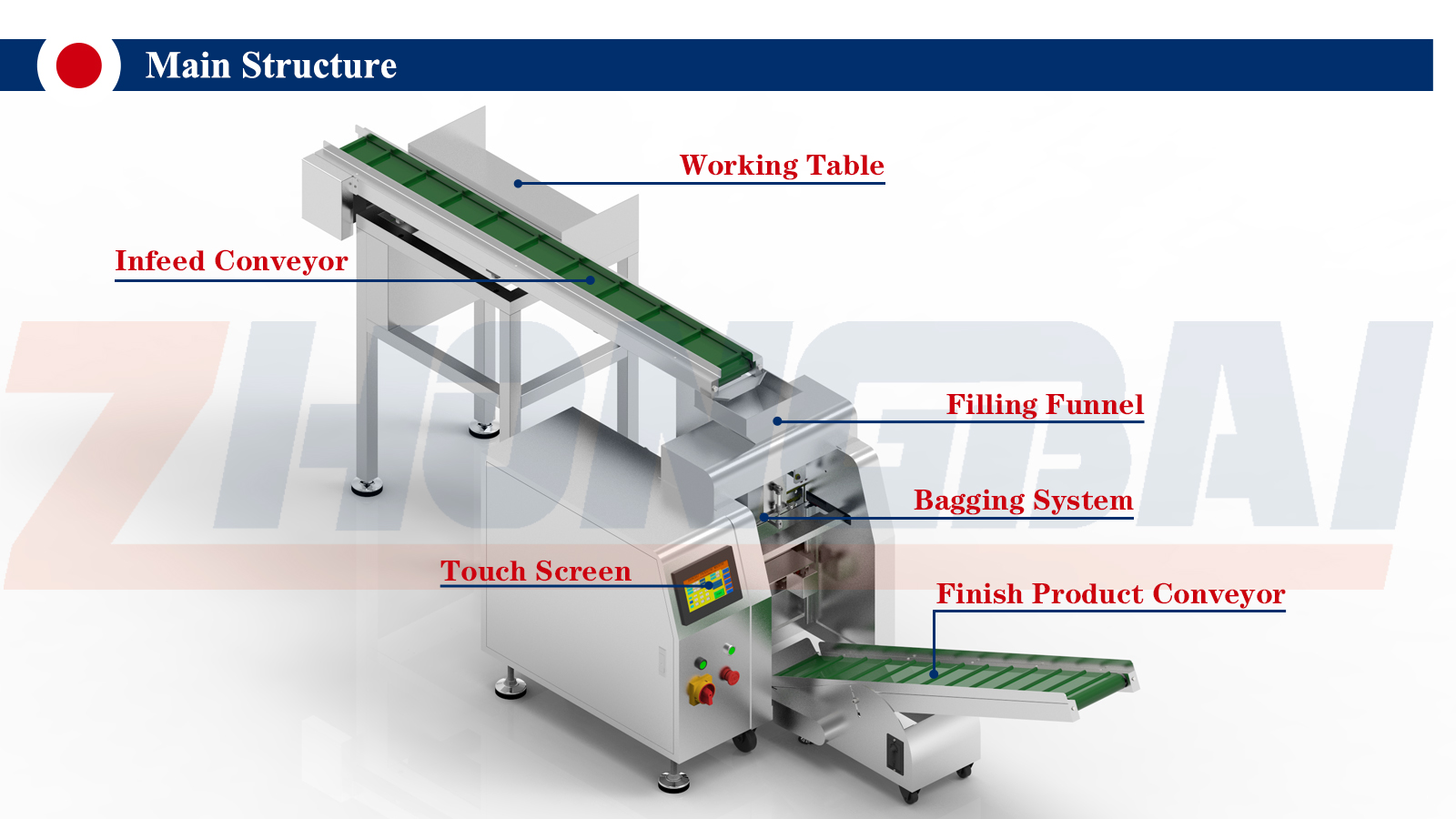

● The infeed conveyor is designed for guaranteed packaging rates or pace rate for operators, wide application and flexible to different sizes of components. Custom conveyor size is available.

● Three operating modes for infeed conveyor:

A. Manual: cycle the conveyor using a footswitch.

B. Automatic: set up continuous feeding of the components for the bagging.

C. Counting: bagger cycles when the sensor detects the pre-set product count.

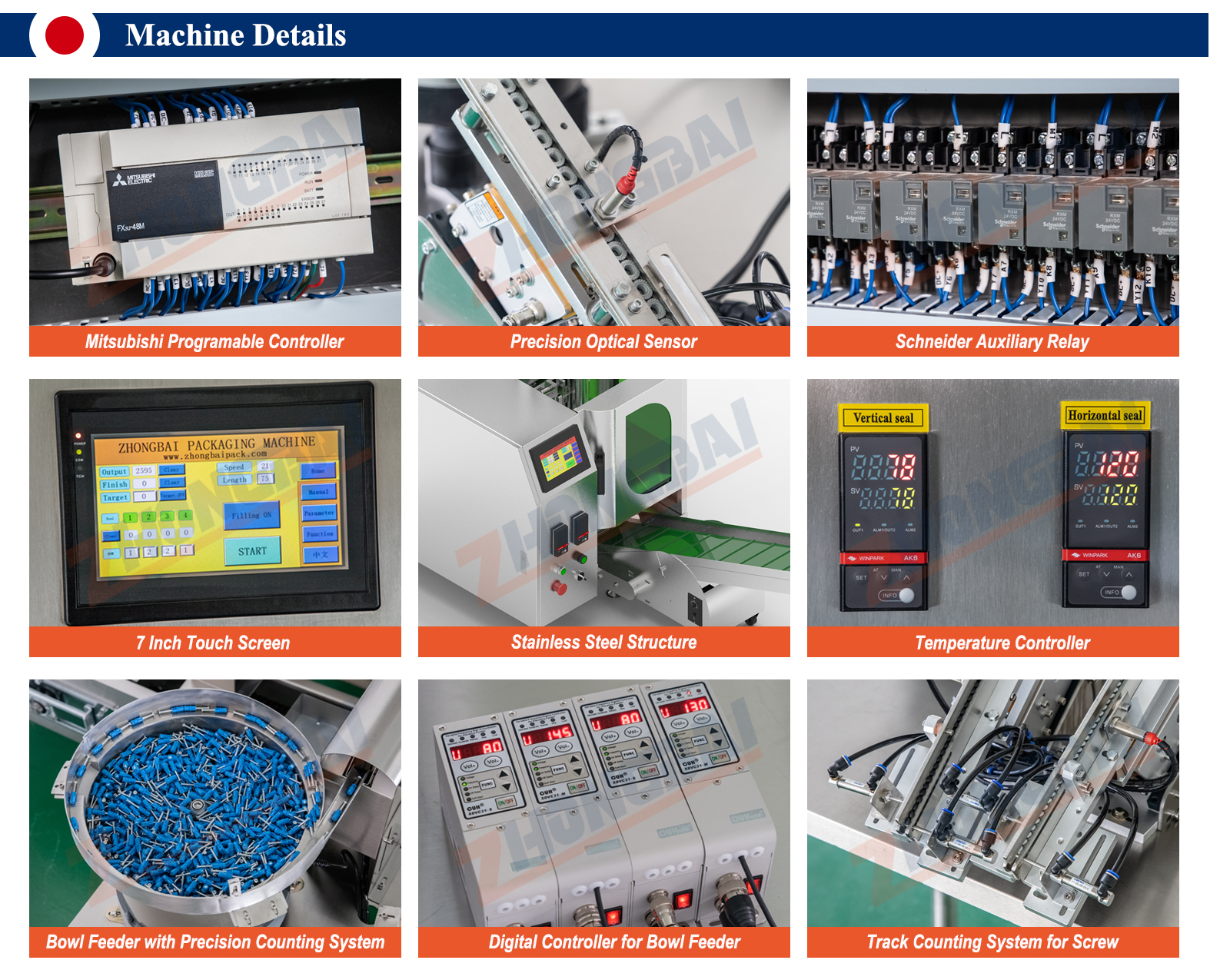

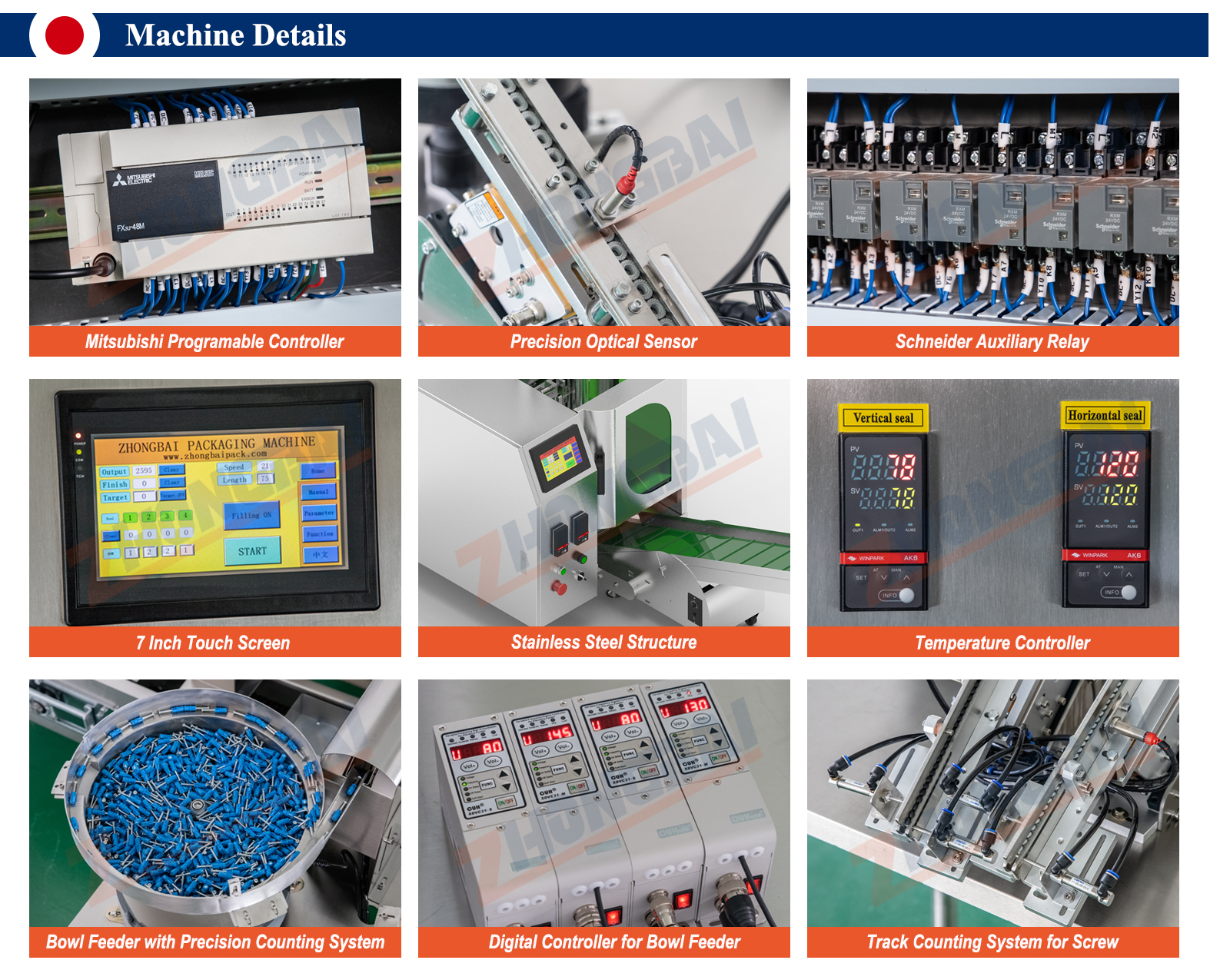

● Mitsubishi PLC control and there is an 7 inch English touchable human-machine operation interface, it is easy to operate.

● Stainless steel structure, it is only necessary to set the needed parameters at the display screen, the control system can automatically optimize and match with the actions, realizing the optimal packing speed.

● An adjustable height load shelf supports the bag during packaging.

● Built-in self-help diagnostics for troubleshooting ensure quick problem-solving.

● ZHONGBAI's advanced programmable control system, ensures the machine running is stable and reliable with easy operation.

● Components conveying, bag feeding, filling, sealing, and output count can be done automatically.